Versatility of Styrene Butadiene Copolymer Resins

Versatility of Styrene Butadiene Copolymer Resins

Styrene butadiene copolymers resins represent a versatile family of resins for adhesive and sealant development. They bond well to many substrates, and their formulation can be easily adjusted to achieve widely varying properties. Adhesives and sealants based on styrene butadiene copolymers (SBCs) are both useful and unusual. They have the solubility and thermoplastic nature of polystyrene.

At ambient temperature, they have the toughness and resilience of an elastomer. This characteristic provides styrene butadiene copolymers adhesives with versatile properties in both adhesive and sealant formulations. Because of their thermoplastic nature, SBC can be easily formulated into either hot-melt adhesives or solvent solutions. They can even be chemically crosslinked via radiation or the use of reactive end groups.

The performance of SBC-based adhesives and sealants majorly depends on the composition of the formulation, which is governed by factors as listed below.

- Selection of the appropriate SBC resin of which many are available

- Addition of tackifiers primarily to modify the rheological properties

- Addition of plasticizers, waxes, or oils primarily to modify the application properties

- Addition of other additives such as antioxidants, UV inhibitors, fillers, etc. to provide sufficient stability for the application process and service conditions.

Let's begin by understanding the basics of SBC resins.

Styrene Butadiene Copolymer Resins - Structure and Key Benefits

Styrene Butadiene Copolymer Resins - Structure and Key Benefits

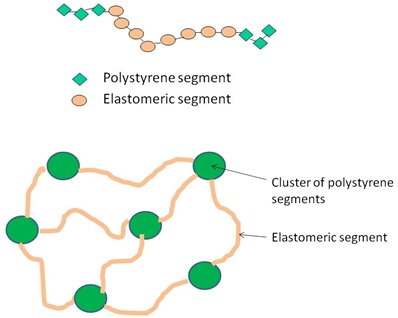

The simplest block copolymer can be visualized as a rubbery elastomeric midblock with one or two thermoplastic (styrene) endblocks. This is illustrated in figure below where,

-

The green diamond like structures represent the thermoplastic endblocks and

-

The circles represent the rubbery midblock.

The key requirement is that the thermoplastic rubber molecules terminate with a hard, glass like endblock that is incompatible with the rubbery midblocks.

Simplified Styrene Butadiene Copolymer molecule (top) and

Simplified Styrene Butadiene Copolymer molecule (top) and

Representation of an SBC structure in bulk (bottom)

This two-phase structure provides an unusual combination of properties. The polystyrene endblock segments form regions or domains separate from the elastomeric midblock segments.

-

At the service temperatures, the polystyrene segments act as physical crosslinks to connect and lock the elastomeric segments in a three dimensional network.

- At higher temperatures, the end segments will soften and the material can flow under stress.

Since these materials are thermoplastic elastomers they have many performance properties of vulcanized elastomers but can be processed easily on conventional thermoplastic processing equipment. The low surface energy of styrene butadiene copolymer resins results in good wetting of low surface energy substrates such as polyolefins.

There is no strong chemical interaction with substrates; however, very good adhesive strength is achieved by the SBC resins ability to conform to the surface and to dissipate energy uniformly throughout the bond area. These factors provide adhesives with high peel strength and toughness.

It is readily apparent why styrene butadiene copolymers are one of the most popular polymers to use in both pressure-sensitive and non-pressure-sensitive applications.

Features of SBC Resins

- One of the most important features of Styrene Butadiene Copolymer adhesives and sealants is their versatility.

- Because of their thermoplastic nature, Styrene Butadiene Copolymer can be easily formulated into either hot-melt adhesives or solvent solutions.

- They can even be chemically crosslinked via radiation or the use of reactive end groups.

- The thermoplastic nature of the end blocks provide good processing properties in the melt form.

Therefore, Styrene Butadiene Copolymers can be used in hot-melt as well as solvent-borne adhesive formulations.

| Advantages |

Disadvantages |

-

Strong, rubbery characteristics at ambient temperatures, but become a viscous fluid at high temperatures

-

Good performance at high and low temperatures

-

Low inherent tack (non-blocking), but can be made pressure-sensitive by the addition of tackifying agents

-

Excellent adhesion - Low surface energy results in good wetting of low surface energy substrates such as polyolefins

-

Good electrical insulating characteristics

-

Can be cured via vulcanization or other chemical methods

-

Relatively low cost - can be compounded with a variety of low cost fillers, additives, and modifiers

-

Clean and non-toxic - many formulations are approved for food contact and medical applications

-

Very high solids content in solution can lead to a reduction in VOC for a constant viscosity

-

Ease of compounding

- Low mixing costs (no need for mastication) as a hot melt

-

Easily dispersed in aliphatic and aromatic solvents

-

Cohesive and adhesive properties can be easily adjusted to the application requirements.

|

-

Complex formulations. Tackifiers, plasticizers, and other additives (e.g., antioxidants) are generally required for practical formulations

- Formulation complexity (two-phase system) requires skill and also requires development time for optimization

-

Creep at elevated temperatures unless crosslinked

-

Certain types (SBS, SIS) require protection for UV and ozone resistance. Hydrogenated types (SEBS and SEPS) have much greater resistance

-

Not generally recommended for immersion applications and not as hydrophobic as butyl compounds

-

Relatively poor resistance to organic solvents and oils

|

Types of SBC Resins - Properties Comparison

Types of SBC Resins - Properties Comparison

The elastomeric segment in a styrenic block copolymer is generally polybutylene, polyisoprene, poly(ethylene-co-butylene), poly(ethylene-co-propylene) resulting in the following four major types of SBC polymers:

Styrene-isoprene/butadiene-styrene (SIBS) is a relatively new copolymer that was developed primarily to replace SIS copolymers. SIBS have become somewhat scarce and expensive due to a shortage of isoprene.

The properties of the most common styrene block copolymers are displayed in

the table below. In general the saturated block copolymers (SEBS and SEPS) are used where:

- Long term thermo-oxidative stability is critical, or

- compatibility with other low polarity adhesive ingredients is required.

Comparison of Styrene Block Copolymers Properties

| Property |

SBS |

SIS |

SEBS |

SEPS |

| Cost (USD / lb) |

0.75 |

1.00 |

1.90 |

2.30 |

| Thermal Stability |

Fair-poor |

Poor |

Excellent |

Excellent |

Midblock

- Mc, g / mol

- Tg, °C

- Solubility parameter (cal/cm3)1/2

|

|

|

|

|

| Tensile Strength, psi |

700-4600 |

1200-3100 |

350-5000 |

300 |

| Elongation, % |

800-1100 |

1200-1300 |

500-750 |

<100 |

| 300% Modulus, psi |

130-400 |

60-200 |

350-800 |

– |

|

Hardness, Shore A

|

50-75 |

30-55 |

65-75 |

70-75 |

Variations in Styrene Butadiene Copolymer Resins

Variations in Styrene Butadiene Copolymer Resins

Major variations in Styrene Butadiene Copolymer resins include:

Mid-Block Type

The strength and stiffness of the block copolymer depends on:

- The chemical nature of the midblock segments

- Their mutual interaction

Block copolymers having the same styrene content, about the same block molecular weight, but different types of midblock display different mechanical properties.

The relative performance properties of the SBS, SIS, SEBS, and SEPS copolymers

in adhesive and sealant formulations are illustrated in the table below. It can be seen from this table

that there is much overlap in the physical properties of these materials, depending on the details of the formulation.

» Find Out How to Use Styrene Block Copolymers to Improve Your Sealants Performance!

The Relative Performance Properties of Styrene Block Copolymers

| Property |

SBS |

SIS |

SEBS |

SEPS

|

| Flexibility |

✔ |

✔ |

✔ |

✔ |

| Tensile strength |

✔ |

✔ |

✔ |

✔ |

| Adhesion |

✔ |

✔ |

✔ |

✔ |

| Tackifiable |

✔ |

✔ |

✔ |

✔ |

| Electrical properties |

✔ |

✔ |

✔ |

✔ |

| Outdoor aging, UV, and oxidation resistance |

|

|

✔ |

✔ |

| High temperature processing stability |

|

|

✔ |

✔ |

| Food contact approval |

Some |

Some |

✔ |

✔ |

| Steam sterilizable for medical applications |

|

|

✔ |

✔ |

| High temperature performance and creep resistance |

|

|

✔ |

✔ |

SBS is primarily employed over SIS where low cost or improved thermal stability is needed. SBS polymers generally have a higher level of hard polystyrene phase and are, thus, harder and stronger than SIS polymers. This benefits formulations where high modulus and load bearing capacity are required.

Because of the higher stiffness of polybutadiene blocks and cohesive strength of the molecular interactions, SBS polymers are generally recommended for non-pressure-sensitive applications such as industrial assembly hot-melts adhesives and sealants.

SEBS polymer has the highest strength and modulus.

SIS has less cohesive strength and thermal stability than the SBS copolymers. As a result, SIS is commonly employed in pressure-sensitive adhesives (PSAs) because of the higher molecular weight between entanglements (Mc) and the lower solubility parameter of isoprene in comparison with butadiene.

The high Mc allows more polymer of a higher molecular weight to be added to the adhesive formula while maintaining adequate softness and an acceptable viscosity.

Molecular Weight

Because of the presence of double bonds in the mid-blocks, both SBS and SIS are vulnerable to thermal, UV, and oxidative degradation. The degradation mechanism is different among Styrene Butadiene Copolymers.

- SIS degrade by chain scission (loss of cohesive strength) while

- Butadiene type copolymers degrade by crosslinking (increased rigidity).

The saturated midblock copolymers (SEBS and SEPS) are resins in which the polyisoprene or polybutadiene is hydrogenated and becomes substantially more stable. They are used where long term thermo- and photo-oxidative stability is critical, or where compatibility with other low polarity adhesive ingredients is required.

- The commercial SEBS polymers have a much better stability during melt processing because their

midblock is saturated polyolefin rubber.

- In addition to PSAs and sealants, SEBS polymers can be used in formulating laminating, contact, and structural adhesives. They can also be

used as oil gels, greases, and masks for chemical milling.

- SEBS polymers are compatible with waxes and can be used as a minor ingredient in wax coatings to improve flexibility.

It is difficult to consider molecular weight alone in selecting a suitable SBC because molecular weight is the consequence of other properties such as styrene content, molecular architecture, etc.

Styrene content or end block molecular weight mapped against the overall Styrene Butadiene Copolymer molecular weight provides a strong tool for mapping the properties of the resin as shown in

the figure below.

SBC Property Direction as Indicated by Styrene Content and Total Molecular Weight

SBC Property Direction as Indicated by Styrene Content and Total Molecular Weight

The SBC polymers generally used in adhesive formulations today, usually have a molecular weight in the range of 60,000 to 200,000. Molecular weight will affect the properties of the SBC polymer, but it has a profound effect on melt viscosity of hot-melt adhesive formulations.

The figure below illustrates the effect of Styrene Butadiene Copolymer molecular weight on melt viscosity.

Effect of SBC Block Molecular Weight Distribution on Melt Viscosity

Styrene Content

The cohesive strength of styrene butadiene copolymer adhesives is primarily determined by its stress-strain behavior, and this is closely related to the volumetric phase ratio of polystyrene endblock to elastomer midblock and to the morphology of these two phases.

As the endblock concentration increases, the shape of the stress-strain curves change as illustrated in the figure below.

- At very low polystyrene concentrations physical crosslinking cannot occur.

- At a concentration of 20-30% the curve exhibits the characteristic of a

vulcanized rubber.

- At concentrations above 33%, the curve exhibits the characteristic of a thermoplastic.

Stress-strain Behavior of SBC with Differing Polystyrene Concentrations

Stress-strain Behavior of SBC with Differing Polystyrene Concentrations

Styrene content is also an important variable in determining the hardness of the SBC polymer. The table below shows the effect of percent styrene content and molecular weight on Shore A hardness measurements. The main Styrene Butadiene Copolymer resins used in adhesive formulations usually have a styrene content of 15-45%.

| Styrene Content, % |

Molecular Weight |

Hardness, Shore A |

| 20 |

160,000 |

47 |

| 30 |

140,000 |

65 |

| 40 |

130,000 |

91 |

Molecular Architecture

Although a wide range of tri-block, di-block, and star SBC architectures are available with styrene contents ranging from 10% to more than 70%, the number of Styrene Butadiene Copolymer products that are useful in adhesive and sealant applications are more limited.

The figure below illustrates the molecular configuration of a styrene-ethylene-butylene-styrene tri-block (SEBS) and di-block (SEB).

Architectural Differences in Di-block and Tri-block SEBS Copolymers

Architectural Differences in Di-block and Tri-block SEBS Copolymers

Di-blocks are especially useful in adhesive formulation in that they can be thought of as diluents for SBC polymers. In this way di-blocks can be used to lower cohesive strength, and improve die cutability (PSA tapes and labels).

Di-blocks are also very useful in adjusting peel strength. They provide lower melt viscosity and the capability of lower solution viscosity at a given solids content. This last characteristic is used to great benefit in the formulation of sprayable adhesives with high solids content.

New multi-arm polymers have been shown to develop higher cohesive strength (tensile strength) than commercial multi-block polymers with a higher styrene content and similar viscosity.

- These new polymers also improve rolling ball tack properties of the adhesive formulation.

- These new polymers show promise in

pressure-sensitive adhesive formulations.

Formulating with SBC Resins

SBC Resin Selection to Meet End-Use Requirements

SBC Resin Selection to Meet End-Use Requirements

As one might expect styrene butadiene copolymer resins can be used in many different forms and industrial applications. The end-use is often dictated by the base polymer and specific formulation ingredients.

- In general SIS resins are used in applications requiring good pressure sensitivity and low cohesive strength (e.g., tapes and labels).

- SBS resins are used where there is greater need for cohesive strength (e.g., industrial hot-melts and sealants). Hydrogenated copolymers are used in applications requiring good weathering, oxidation, and UV resistance.

The table below provides a list of styrene butadiene copolymer types, their benefits in adhesives or sealants, and common applications. Of course, there is significant overlap in this selection process and end-use properties can be significantly modified by formulation so as to adapt to more than one application.

Features & Applications of SBC Resins in Adhesives and Sealants

| SBC Type |

Structure |

Features / Benefits |

Example Applications |

Styrene

Butadiene

Styrene |

31% styrene, linear, 16% diblock |

High strength |

Construction mastic |

| 28% styrene, linear, 16% diblock |

Low viscosity |

Bookbinding

|

| 23% styrene, radial, 16% diblock |

For aliphatic solvents, color stability |

Polystyrene foam mastic |

| 31% styrene, linear, 78% diblock |

Low cohesive strength |

Sealants |

| 39% styrene, radial, 10% diblock |

High shear, color stability |

Disposable products (diapers, etc.) |

| Styrene Isoprene Styrene |

15% styrene, linear, 17% diblock |

Good balance of properties |

Labels, tapes, disposable products

|

| 22% styrene, linear, 15% diblock |

High shear and SAFT* (shear adhesive failure temperature) |

| 15% styrene, linear, 38% diblock |

High peel, low cohesive strength |

| 18% styrene, linear, 0% diblock |

High shear, color stability |

| 17% styrene, linear, 33% diblock |

High peel, low viscosity |

| Styrene-butadiene-ethylene-styrene |

30% styrene, linear, 0% diblock |

High strength |

Disposable products |

| 31% styrene, linear, 0% diblock |

Balance strength and viscosity |

Sealants |

| 13% styrene, linear, 29% diblock |

Soft |

PSAs, sealants |

| Material Selector: View all SBC formulations for adhesives and sealants here » |

SBC Resins in Solvent-borne Sealants

Styrene block copolymers have found many different applications because they can be formulated to provide a wide range of properties. They are soluble in common solvents and can be applied as an extrudable grouting, caulk, or sealant. They can also be applied as a viscous mastic or even as an aerosol coating.

Compared to other elastomers, some of the advantages of SBCs in solvent-borne sealants are:

- Polymers are directly soluble — no milling necessary

- Solution times are short — greater productivity and efficiency

- Solutions are more uniform — better control and reproducibility

- Solution viscosity is lower — higher percent solids, lower solvent cost, greater thickness build

- Solutions are stable — longer shelf life

The existence of two separate and essentially incompatible segments in the same molecule must be taken into account when the SBC polymers are formulated as a solvent-borne system.

- Aromatic solvents dissolve both polybutadiene and polystyrene and are good solvents for these polymers.

- Aliphatic solvents dissolve the polybutadiene blocks and, therefore, will dissolve only block polymers with low styrene content.

- Blends of aliphatic and aromatic or polar solvents can also be used.

The necessary amount of solvent is determined by the molecular weight and polystyrene content of the base polymer.

The main difference between SBC solvent-borne and hot-melt sealant formulations is that, in the solvent-borne systems the viscosity can be controlled by selection and concentration of solvent and by the addition of fillers. As a result, solvent borne SBC sealants do not require plasticizers which are usually incorporated into hot melt sealants to adjust melt viscosity.

Plasticizers in sealants can be a problem with regard to surface tack (dirt pickup) and volatilization (fogging and reduction in elongation over time).

SBC sealants have a high degree of cohesive strength and elongation for structural applications. However, peel strength values will differ depending on the formulation and substrate. They have excellent peel adhesion to wood and other porous substrates that are used in the building and construction industry. However, the peel strength for hot-melt sealants is generally considered to be higher on non-porous substrates such as glass and aluminum.

There is a growing use of SBC adhesives and sealants in construction projects for adhering wall panels and plywood subflooring because of their high uncured (green) strength. They are low cost products that can be used in interior applications where UV exposure is not an issue.

Solvents in these sealants are mostly naphtha with enough toluene added to dissolve the polymer.

The starting composition in the table below is an example of a SBS-based adhesive/sealant for the assembly of building and construction components. When formulated with suitable solvents and fillers, this composition can be manufactured to have a wide range of viscosity properties. With an additive, oxygen bomb aging exceeds current building requirements.

| Components |

Parts by Weight |

| SBS Polymer |

100 |

| End block hydrocarbon resin |

75 |

| Soft clay |

200 |

| Zinc dibutyl dithiocarbamate |

2 |

| Stabilizer |

1 |

| Solvents |

As required |

| Properties |

| Lap shear strength (wood / wood), psi |

590 |

High Viscosity Construction Mastic-based on SBS Polymer1

Saturated SEBS thermoplastic polymers are used for outdoor and higher temperature applications or when there is a need for a clear sealant composition. The high tensile strength and good aging characteristics of this polymer provide high performance and long service life.

A solvent-based clear SEBS sealant formulation is provided in the table below. Fillers are not used in this formulation due to the need for clarity. However, if clarity is not a requirement, fillers can be added to reduce cost, shrinkage, and for non-sag properties.

| Components |

Parts by Weight |

| SEBS Polymer |

100 |

| End block hydrocarbon resin |

115 |

| VM&P Naphtha |

22 |

| Propyl acetate |

28 |

| Toluene |

12 |

Solvent-based Clear SEBS Sealant2

Find Suitable Styrene Butadiene Copolymer Grade

View a wide range of styrene butadiene copolymers (SBS, SEBS, SEPS, SIS) available in the market today, analyze technical data of each product, get technical assistance or request samples.

References

- Harlan, J.T, Petterson, L.A., "Thermoplastic Rubber (A-B-A Block Copolymers) in Adhesives", Chapter 19 in Handbook of Adhesives, 2nd ed., I. Skeist, ed., van Nostrand Reinhold, New York, 1977 and Ewins, E.E. and Davis, G.A., "Thermoplastic Rubber (A-B-A Block Copolymers) in Adhesives", Chapter 13 in Handbook of Adhesives, 3rd ed., I. Skeist, ed., van Nostrand Reinhold, New York, 1991.

-

Eastman Sealants Technical Tip TT-84, "Clear Thermoplastic Sealants Using Eastman Hydrocarbon Resins", Eastman Chemical Company.