Versatility of Ethylene Copolymers

Versatility of Ethylene Copolymers

Ethylene copolymers and terpolymers are widely used in manufacturing hot-melt

adhesives due to their mechanical cohesion and adhesive properties.

They are highly flexible products, compatible with many other polymers and

additives. They are easy to process and offer an excellent cost-performance ratio.

Ethylene copolymers and terpolymers are closely tailored to the requirements of the

adhesives industry.

Ethylene copolymer-based hot-melts present:

- A very good adhesion on various substrates (such as paper, wood, plastics, metals...)

- A broad operating window

Let’s explore the chemistries, key benefits and applications provided by ethylene copolymers in detail...

Chemistries of Ethylene Copolymers

Chemistries of Ethylene Copolymers

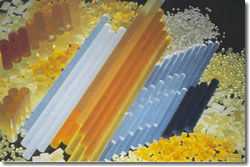

Ethylene copolymers are used in many applications such as packaging, woodworking, medical, transportation or assembly. A wide range of products are available in the market to provide formulators with optimum polymer performances to match the most severe requirements.

There are several chemistries of ethylene copolymers, such as:

Ethylene Vinyl Acetate (EVA) Copolymers

Ethylene vinyl acetates are leading polymers for hot-melt manufacturing due to

their high versatility. EVA-based hot-melts are able to fulfill various requirements in applications, such as packaging, bookbinding or label sticking.

Due to its chemical structure, the ethylene vinyl acetates range:

- Is highly flexible

- Delivers high cohesive strength and compatibility

- Ensures excellent adhesion to a wide range of substrates

- Is highly resistant to rupture

Thanks to their high compatibility, they can be formulated in combination with both natural or synthetic tackifiers, a large range of PE waxes, modified waxes

or plasticizers and their intrinsic stability can be enhanced by the right choice of antioxidant or UV/light stabilizers.

The structure of random ethylene vinyl acetate copolymers obtained by high-pressure radical polymerization is given below:

Structure of Random Ethylene Vinyl Acetate Copolymer

Ethylene Acrylates Copolymers (EBA, EMA, 2EHA)

Ethylene acrylic ester copolymers can be divided into 3 product families

according to the type of acrylic derivative:

| Key Benefits of Ethylene Acrylic Ester Copolymers |

- Excellent thermal stability

- Excellent adherence to many substrates (For example: polyethylene, polystyrene, polypropylene, OPP, etc.)

- Good chemical resistance

- Good elastic properties

- Excellent mechanical behavior at low temperature

|

These qualities make them suitable for many applications including HMA or HMPSA for example, in packaging or disposables.

The structure of random ethylene acrylic ester copolymers is given below:

Structure of Random Ethylene Acrylic Ester Copolymers

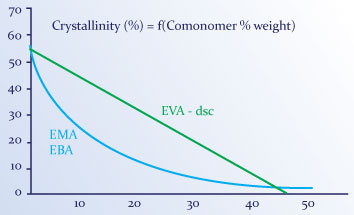

Acrylic ester decreases the crystallinity of the polymer, which in turn widens the operating window of the adhesive.

Ethylene Acrylic Ester Terpolymers

Ethylene acrylic ester terpolymers can be divided into several product families depending on:

- The acrylic ester type (methyl, ethyl or butyl acrylate)

- The third monomer used (MAH: maleic anhydride, GMA: glycidyl methacrylate)

The structures of random ethylene vinyl acetate/maleic anhydride terpolymers obtained by high pressure radical polymerization is shown below:

Structure of Random Ethylene Vinyl Acetate - Maleic Anhydride Terpolymers

Structure of Random Ethylene Vinyl Acetate - Maleic Anhydride Terpolymers

These products are characterized by reactivity, crystallinity and fluidity making them easy to use and readily compatible with the different types of other polymers and additives.

EVA can react with other functional polymers in order to create chemical bonds

that can increase final adhesion properties, heat resistance or long-term aging properties. This is due to the presence of glycidyl methacrylate (GMA) or maleic anhydride (MAH) groups.

Acrylic ester decreases the crystallinity of the polymer, which

in turn widens the operating window of the adhesives. It also helps in keeping

good mechanical properties and offers excellent thermal stability with limited viscosity change and discoloration (when formulated with a suitable antioxidant).

Maleic anhydride increases adhesion to polar substrates and allows the creation of chemical bonds onto substrates such as metals, polymers, metallized products, cellulosic substrates, rubbers, non-wovens, etc.

Ethylene ester acrylic terpolymers are used in the following adhesive systems, for example:

- In thermo-adhesive films, they are used in the interior liners of automobiles.

- In hot-melts, they can be used in the formulation of packaging and bookbinding applications.

Ethylene Vinyl Acetate Terpolymers

Ethylene vinyl acetate terpolymers are random ethylene vinyl acetate/maleic anhydride terpolymers. Maleic anhydride improves the adhesion properties of the final hot-melt formulation. Its structure is given below:

Ethylene Vinyl Acetate Terpolymers

Ethylene vinyl acetate terpolymers are highly recommended for the bonding of low surface energy substrates or for dissimilar materials (plastic to cardboard or UV varnished coatings). They are typically used to make:

- Thermo-adhesive films for the textile and automobile industries

- Extrudable hot-melt adhesives for coating various materials

- Many hot-melt formulations for packaging and assembly

» View All the Commercially Available Ethylene Copolymers Here!

This adhesives database is available to all, free of charge. You can filter down your options by suitable resin, system or application (adhesives, sealants...), supplier and regional availability.

Benefits and Features of Ethylene Copolymers

Benefits and Features of Ethylene Copolymers

With a very broad range of copolymer content resulting in versatile balance of adhesion/cohesion properties and a variety of molecular weight directly linked to viscosity and rheological behavior, ethylene copolymers are leading technology for hot-melt formulations.

Formulators can adjust their formulation to fulfill technical requirements of many applications requiring long or short open time, resistance to elevated or cold temperatures and many other performances.

Adhesion on Difficult Substrates with Ethylene Copolymers

Ethylene copolymer-based hot-melts are able to adhere to substrates ranging from untreated polyethylene to aluminum, due to their intrinsic adhesion properties and their high formulation flexibility.

Ethylene copolymer-based hot-melts are able to adhere to substrates ranging from untreated polyethylene to aluminum, due to their intrinsic adhesion properties and their high formulation flexibility.

On the most difficult substrates and when high performances are required, these products will open new possibilities for ethylene copolymer-based hot-melts.

Formulation Flexibility with Ethylene Copolymers

When formulating hot-melts, formulators target a specific adhesion/cohesion balance which will impact on final product performances, such as:

When formulating hot-melts, formulators target a specific adhesion/cohesion balance which will impact on final product performances, such as:

- Peel properties

- SAFT resistance

- Low temperature flexibility

One typical way to adjust this adhesion/cohesion balance is to formulate with compatible or partially/fully incompatible tackifiers.

Heat Resistance with Ethylene Copolymers

In many applications, such as transportation, industrial assembly or specialty packaging, high heat resistance is required. The large range of EVA grades available will provide formulators with many possibilities for matching the most difficult requirements.

In many applications, such as transportation, industrial assembly or specialty packaging, high heat resistance is required. The large range of EVA grades available will provide formulators with many possibilities for matching the most difficult requirements.

However, when a high heat resistance is needed, whilst keeping lower viscosity for application efficiency, an ethylene acrylate copolymer can be a premium choice.

Heat Stability with Ethylene Copolymers

In order to prevent the negative impact of temperature during manufacturing and application of ethylene copolymer-based hot-melts, it is absolutely necessary to use an appropriate antioxidant in hot-melt formulations.

In order to prevent the negative impact of temperature during manufacturing and application of ethylene copolymer-based hot-melts, it is absolutely necessary to use an appropriate antioxidant in hot-melt formulations.

Ethylene copolymer-based hot-melts present a high heat stability which can be improved by using hydrogenated tackifiers and stable plasticizers or oils.

When very long heat stability is needed with limited fumes or odors, ethylene acrylate copolymers can be an interesting alternative.

Low Temperature Resistance with Ethylene Copolymers

For applications such as ice creams or frozen food packaging, hot-melts have to maintain high level of adhesion and flexibility at -40°C which is known as a good "deep-freeze" resistance. The flexibility of an ethylene copolymer-based hot-melt is highly linked to its glass transition temperature (Tg).

For applications such as ice creams or frozen food packaging, hot-melts have to maintain high level of adhesion and flexibility at -40°C which is known as a good "deep-freeze" resistance. The flexibility of an ethylene copolymer-based hot-melt is highly linked to its glass transition temperature (Tg).

Lowest the Tg, the best would be the deep-freeze performances.

For this type of application, high copolymer content EVA and EBA products are highly recommended.

Low Application Temperature with Ethylene Copolymers

Thanks to the availability of high MFI grades, formulators can adjust the melt viscosity of their formulation in order to facilitate application at lower temperatures than usual in many packaging or assembly applications.

Thanks to the availability of high MFI grades, formulators can adjust the melt viscosity of their formulation in order to facilitate application at lower temperatures than usual in many packaging or assembly applications.

With the high formulation versatility of ethylene copolymers, the adhesion/cohesion balance can be preserved even with a product applicable at temperatures as low as 130°C, resulting in reduced maintenance and energy cost.

A lower application temperature may also result in less fumes and odor. These performances can be enhanced by the high thermal stability and high adhesion performances of hot-melts, which will be chosen when formulators want to achieve high performances and long-term aging properties with a low application temperature hot-melt.

Processability with Ethylene Copolymers

Thanks to their unique mechanical behavior (high flexibility, high break resistance) and their broad compatibility with other polymers or additives, ethylene copolymers are a good option for formulating hot-melts which can meet the rheological requirements of many application devices with a large operating window.

Applications with a Large Operating Window

Applications with a Large Operating Window

Ethylene copolymers can be formulated to be applied by extrusion, by roll, spray or spiral spray. This high versatility is one of the main reasons why this technology is the leading choice for hot-melt formulations.

Chemical Reactivity of Ethylene Copolymers

The presence of maleic anhydride or glycidyl methacrylate monomers can react with other functions in order to create chemical bonds which can increase final adhesion properties, heat resistance or long-term aging properties.

Having learnt about chemistries of ethylene copolymers available and their benefits, now explore the use of ethylene copolymers in different formulations.

Ethylene Copolymers in Hot-melt Systems

Ethylene Copolymers in Hot-melt Systems

Ethylene copolymers are leading materials for formulating hot-melts (pressure sensitive

and non-pressure sensitive) adhesives suitable for applications, such as packaging, bookbinding, wood binding, and many other industrial applications.

Ethylene copolymers are leading materials for formulating hot-melts (pressure sensitive

and non-pressure sensitive) adhesives suitable for applications, such as packaging, bookbinding, wood binding, and many other industrial applications.

This success is due to the high technical versatility of ethylene copolymer-based formulations which can fulfill highly demanding technical requirements covering both long open time and fast setting time, resistance to very low temperatures (-40°C) or very high temperatures (+80°C) with very high thermal- and UV stability for water-white formulations.

The key parameters for choosing the right base polymer for your formulations are:

#1 Choice of Copolymer

The copolymer selection will depend on final properties to be achieved.

EVA products are the right choice for general purpose hot-melts for packaging and bookbinding applications or to reach high temperature resistance in transportation or assembly. High VA content EVA would also be an interesting polymer for formulating hot-melt pressure-sensitive (HMPSA) in applications, such as bottle labeling or sanitary.

Ethylene acrylic ester copolymers polymers have a lower glass transition temperature (Tg) than EVA and provide a better adhesion to difficult substrates as well as better performances at very low temperatures. These polymers will help formulators to achieve very high performances in deep-freeze applications or when a high level of adhesion is required (varnished carboard, plastic to paper bonding).

Ethylene acrylic ester copolymers-based hot-melts also provide a very high resistance to degradation and low odor when formulated with the right tackifiers and preservatives.

For the most challenging bonding (UV-varnished substrates or demanding aging test), the "Ethylene

acrylic esters/Maleic anhydride" or "Ethylene vinyl acetate/Maleic anhydride" terpolymers will be the ultimate choice for achieving very high performances.

#2 Content of Copolymer

The copolymer content is a key parameter to adjust the adhesion/cohesion balance in hot-melt formulations as well as the performances at low or high temperatures. This copolymer content strongly impacts the polymer crystallinity with a high impact on the mechanical performances of the formulated hot-melts.

Crystallinity (%) = f(Comonomer % weight)

Crystallinity (%) = f(Comonomer % weight)

#3 Melt Flow Index (MFI)

This parameter influences the polymer's viscosity. The longer the polymer chain, the higher the viscosity, and hence the lower the melt flow index. A lower MFI will result in:

- Greater mechanical strength

- Higher ring and ball softening point

- Higher performances at high temperature (SAFT or PAFT tests)

- Increased hot-melt viscosity

- A lower MFI also influences open- and setting time strongly

Ethylene Copolymers in Hot-melt Pressure-sensitive Adhesives

Even though styrene block copolymers (SBCs) are the most common polymer base for formulating pressure-sensitive hot-melts, ethylene copolymers can also be a good choice, being able to match highly demanding technical requirements in applications, such as bottle labeling, bookbinding or specialty labels.

In this type of adhesive, the flexibility provided by a high content of vinyl acetate or acrylate (i.e. more than 30%) is enhanced by adding a plasticizer, which ensures the "sticky" effect at ambient temperature.

Ethylene copolymers-based hot-melt pressure-sensitive adhesives can provide very high adhesion on difficult substrates, such as untreated polyolefins or various plastics as well as high color stability in water-white or white formulations.

For HMPSA formulations, high copolymer content and high MFI are preferred as they present a lower glass transition temperature as well as a lower crystallinity.

A broad range of plasticizers or oils, such as phthalates, benzoates, paraffinic

oils, poly-isobutylene are used in combination with ethylene copolymer-based

hot-melt pressure-sensitive adhesives to adjust viscosity, reduce cost or

enhance adhesion properties.

Ethylene Copolymers in Hot-melt Adhesives

Ethylene copolymers are the leading polymers for manufacturing hot-melts. The key applications include packaging, bookbinding, woodworking and various assemblies.

Ethylene copolymer-based hot-melts are able to fulfill demanding technical requirements which include adhesion, application and aging issues.

- When high mechanical strength is needed (for example, edge banding) the

low comonomer content and low MFI products are widely used.

- When high adhesion or low temperature performances are required (for example, polyolefins bonding, deep freeze applications),

high copolymer content and high MFI is recommended.

A broad range of waxes, such as PE waxes, micro-crystalline waxes or functionalized waxes are used in combination with ethylene copolymer-based hot-melts including to adjust viscosity, reduce cost or enhance adhesion properties.

In applications, such as woodworking or bookbinding, some fillers/pigments are added to color the hot-melt

and enhance mechanical properties or reduce cost.

All these polymers can be formulated with a wide range of tackifying resins such as rosin derivatives or hydrocarbon resins. Water-white hot-melts can be formulated using hydrogenated tackifiers.

A preservative system is always added to protect the hot-melt from thermal degradation during manufacturing and application as well as a UV/light stabilizer when needed.

Thermo-adhesive Films

Thermo-adhesive Films

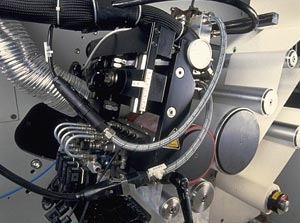

EVA and ethylene acrylic ester-based thermo-reactivable films are a very efficient way to bond various substrates using continuous or discontinuous processes including calendering, press or injection as illustrated below:

Bonding Ethylene Copolymers with Substrates Using Continuous or Discontinuous Processes

This technology is widely used to bond plastic films, fabrics, foams or metals in many applications, for example automotive, textile or furniture industry.

"Ethylene acrylic esters/Maleic

anhydride" or "Ethylene vinyl acetate/Maleic anhydride" and many EVA products are key choices for this application.

Depending on substrates to be bonded a multi-layer films can be used. Original properties of bonded substrates will be preserved and additional performances like barrier effect can be added.